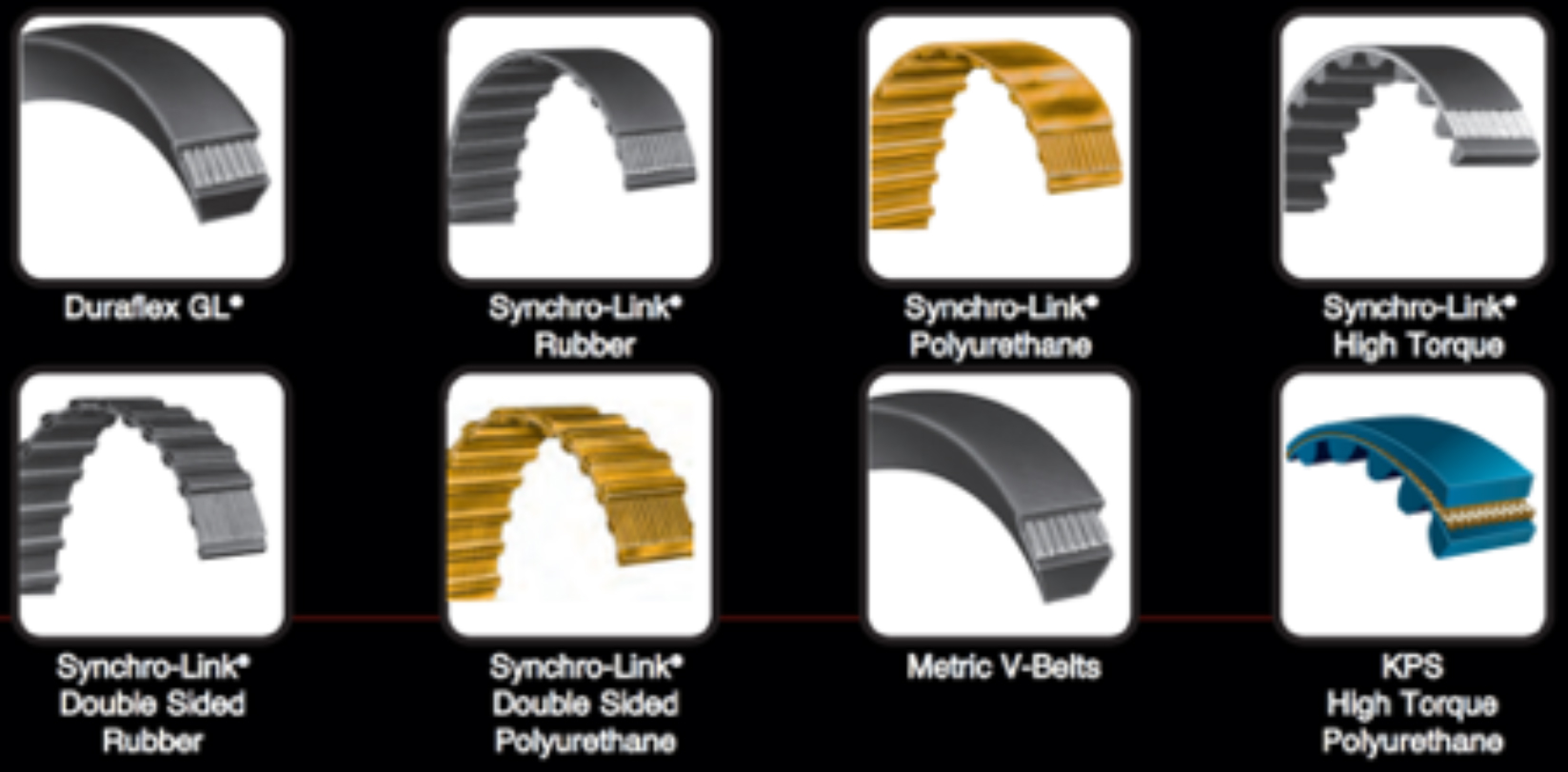

Industrial V-belts

V belts solved the slippage and alignment problem. It is now the basic belt for power transmission. They provide the best combination of traction, speed of movement, load of the bearings, and long service life.

Industrial Timing Belts

Imperial Pitch Belts - XL, L, H, XH This classic trapezoidal pitch is the original timing belt tooth design. This tooth pitch is commonly used for conveying applications. The tooth profile is fairly low and has a large surface area at the tip of the tooth providing good support on sliding conveyor surfaces.

-

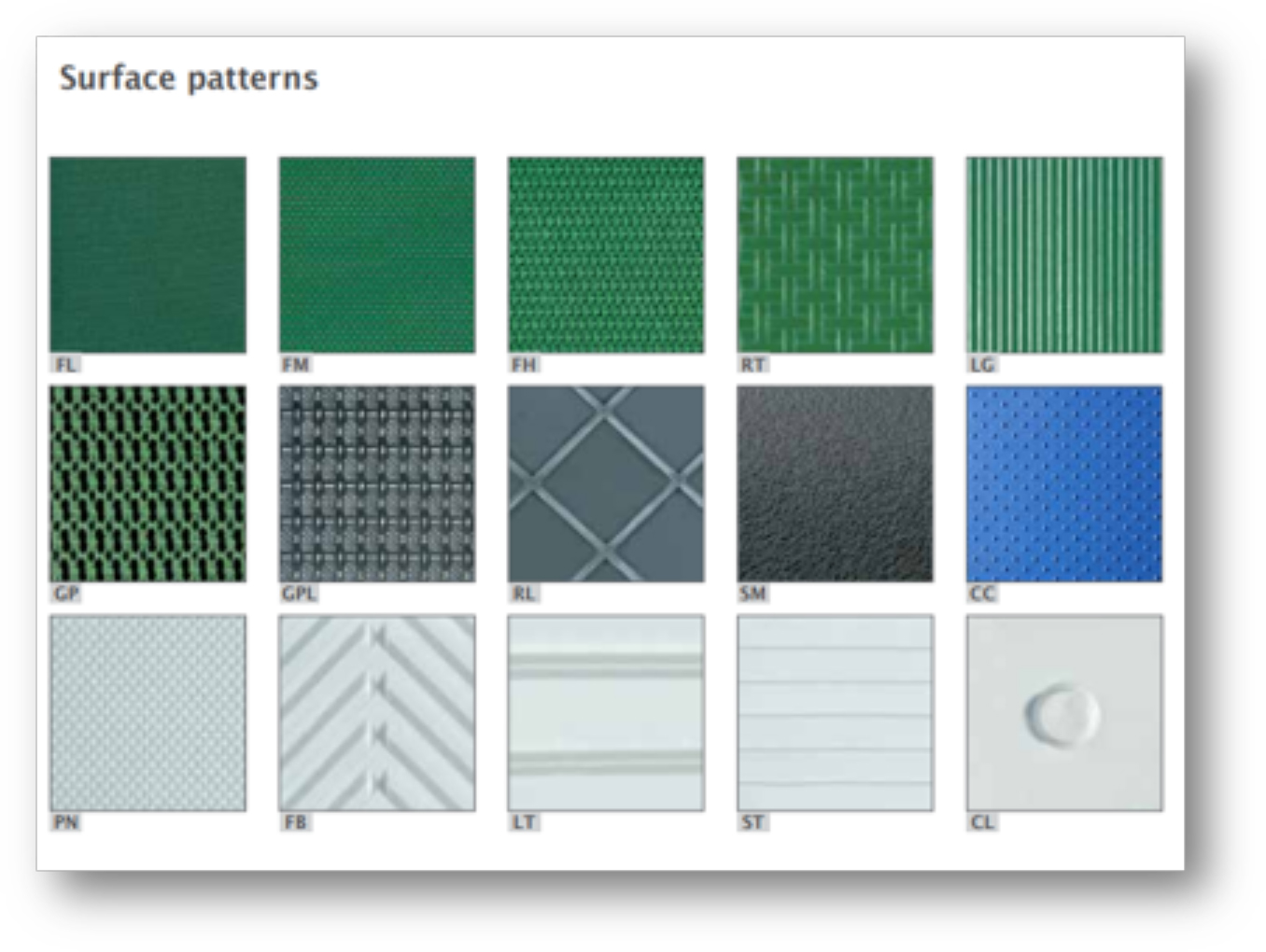

CONVEYOR AND PROCESS BELT / HP-DET-XW-P / HP

2M5 U0-U2 HP W S A

-

CONVEYOR AND PROCESS BELT / HP-DET-XW-P / HP

2M5 U0-U2 HP PN W A

-

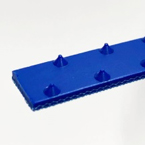

CONVEYOR AND PROCESS BELT / HP-DET-XW-P / HP

2M5 U0-U7 HP LG BLUE S A

-

CONVEYOR AND PROCESS BELT / HP-DET-XW-P / HP

2M5 U0-U8 HP CC BLUE

Toothed belt

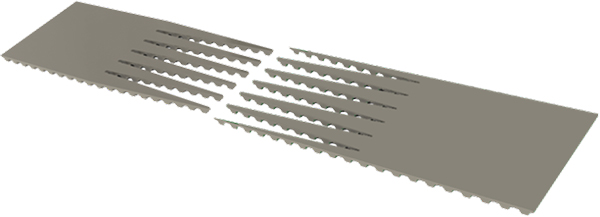

Industrial Tooth Pitch Comparison

We understand that every customer’s need is different. Our experience in a diverse range of industries, coupled with expert engineers and a wide range of product offering allows us to analyse your business situation and offer custom-made solutions.

T Pitch Belts - T2.5, T5, T10, T20 These metric trapezoidal pitches are similar to imperial pitches, also commonly used for conveying applications, yet have a slightly deeper tooth engagement than imperial profiles. The tooth meshing is more reliable. However, backlash can be slightly greater.

AT Pitch Belts - AT5, AT10, AT20 This pitch was developed to enable higher load carrying capacity combined with low backlash. The stronger and stiffer tooth makes these belts ideal for linear positioning and motion control, but may require larger pulley diameters.

AT Pitch Belts - AT5, AT10, AT20 This pitch was developed to enable higher load carrying capacity combined with low backlash. The stronger and stiffer tooth makes these belts ideal for linear positioning and motion control, but may require larger pulley diameters.

STD Pitch Belts - STD5, STD8 This tooth pitch provides superior load distribution, low backlash, and reduced wear and noise characteristics. It is an excellent profile for linear positioning and power transmission applications.

HTD Pitch Belts - HTD5, HTD8, HTD14 This rounded tooth pitch is similar to STD, and is also an excellent profile for linear and rotary positioning and power transmission applications, yet has deeper tooth engagement. Note that the HTD pitch may exhibit slight increases in noise and wear.

Polyurethane Weldable Belts

Polyurethane Weldable Belts are for use in low torque situations and may be purchased in various lengths or cut to length and joined, either by a staple, gluing or welding. United Belt provides different weldable belts with different diameter, length and type in order to meet customers’ desire tensile strength and the ambient conditions.

-

65° Shore A

PU60A soft

Blue smooth

-

76° Shore A

PU70A

Ultramarine blue smooth

-

80° Shore A

PU75A

Red smooth

-

80° Shore A

PU75A

Sky blue smooth

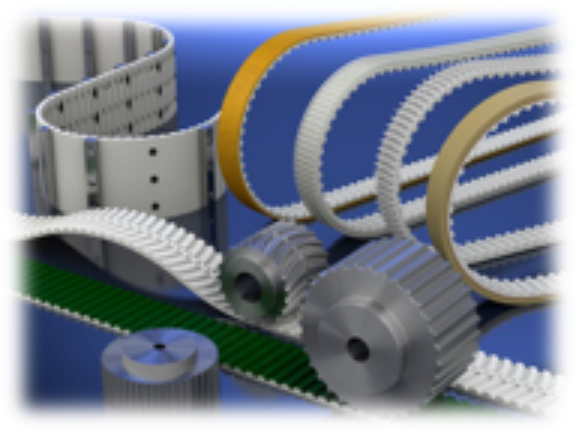

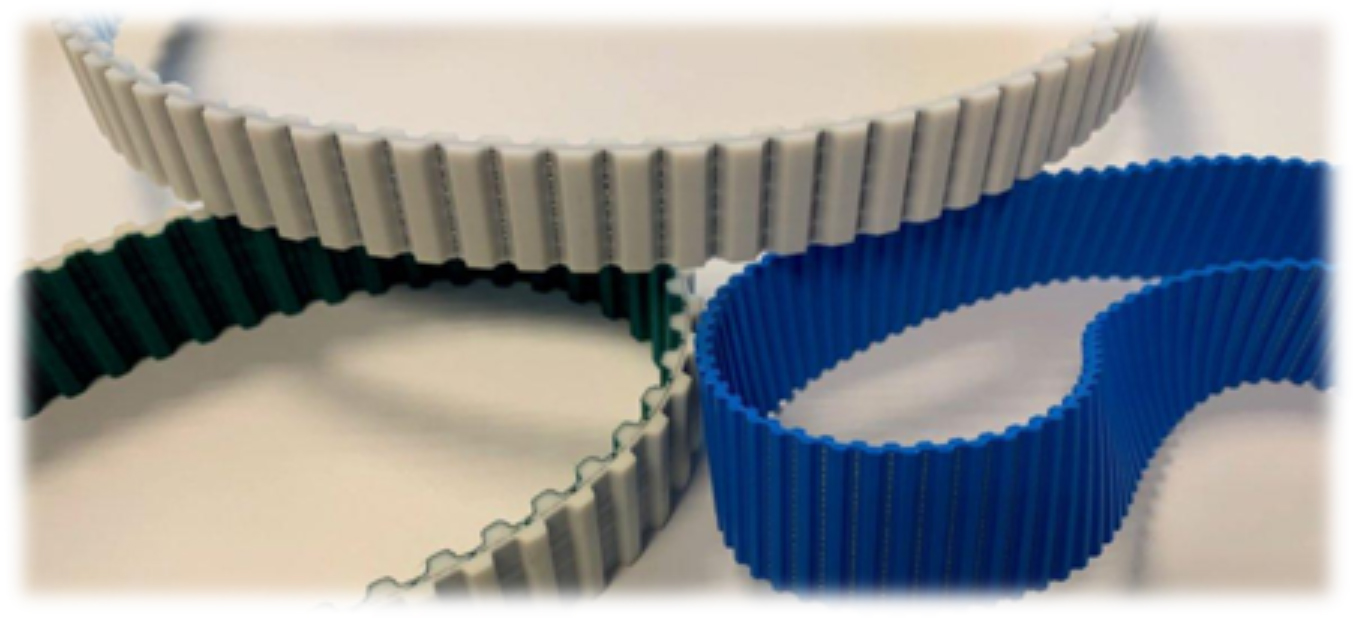

Polyurethane Timing Belts

Polyurethane open-ended Timing Belts assure high quality due to tight tolerance and excellent dimensional stability. On request the addition of a polyamide coating on the back and/or tooth face is possible during production. Open-end polyurethane timing belts can be supplied as open length rolls, or as endless jointed belts.

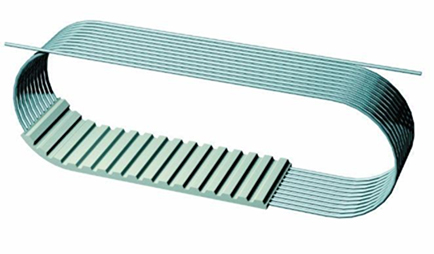

Timing Belts Double Sided

Double-toothed belts are used for drives with axles that rotate in opposite directions.

The most common types are available in the double-toothed version, both in PU and neoprene.

In addition, it is possible to make special double-toothed belts in PU. A standard toothed belt is coated with 90 ° Shore PU in which the desired tooth shape is milled. In this way it is even possible to create two different tooth shapes on one toothed belt.

Timing Belt Joints

Endless with a splice

The standard PU timing belts are made endless by using a finger joint..

This joint has about 50% of the strength compared to a truly endless (flex/moulded) timing belt but is used for almost all transport solutions.

Gewikkeld/Flex

For drives and heavy transport a truly endless timing belt is often used.

These belts are available in the most standard lengths and are stock items.

If longer than 1500 mm the belts will be produced especially on length (flex belts) and are deliverable up to a maximum length of 20.000 mm – always a multiple of the tooth type.

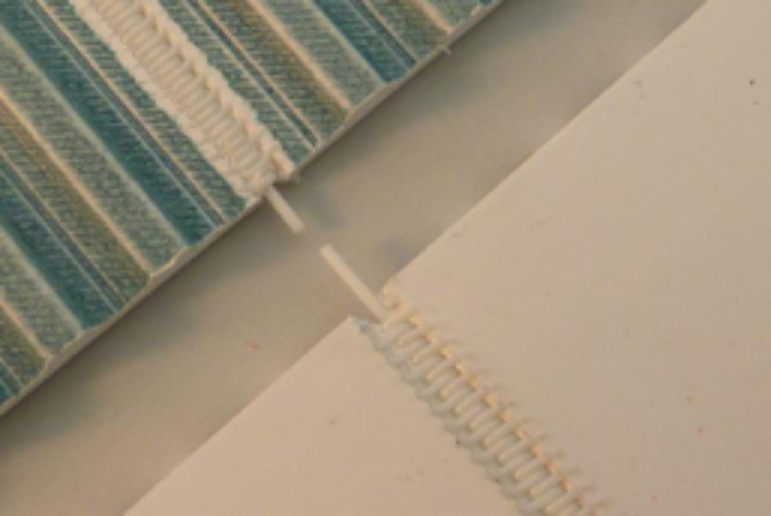

Pin Join

The timing belt joint PIN-JOIN is designed for a singular connection of timing belts directly into the application on site.

The Pin Join timing belt can be fitted as a quick assembly when required, with this system a toothed belt can be changed within 15 minutes.

This connection is also possible for all common types of belt including double sided toothed belts.

The Pin Join timing belt can also be used to Join belts with coatings and cleats.

The maximum load is 50% of the maximum load of an endless welded belt. However, it is also possible to produce an extended Pin Join connector, should the belt be subjected to heavier loads.

Breco C, DC, DC-pro Connector

These connectors are like the Pin Join connector a mechanical connector, but only in combination with Breco ATN timing belts.

In difference to the Pin Join connector this connector can be disassembled.

Hinge Joint

For drives and heavy transport a truly endless timing belt is often used.

1. Open End PU Timing Belts

2. Profiles Attached PU Timing Belts

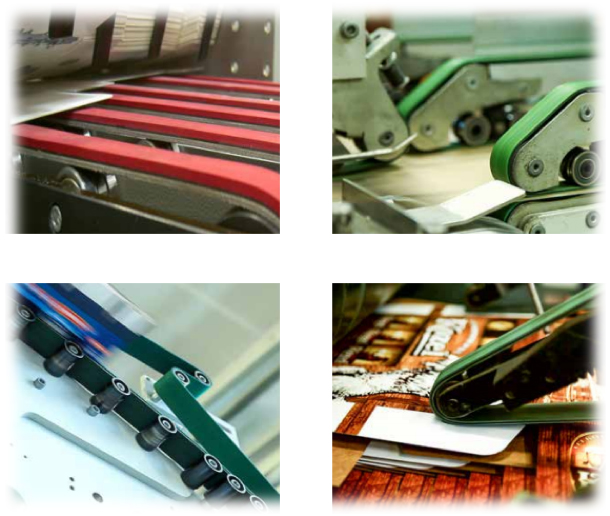

Conveyor Belts

Conveyor belt is one of various devices that provide mechanized movement of material, as in a factory.

United Belt provides different kinds of conveyor belts which can be widely use in various industries such as food industry, airport, automotive, etc.

-

PU60A

Transparent smooth

-

PU60A

Sky blue smooth

-

PU60A

Ultramarine blue smooth

-

PU60A

19 x 8 mm transparent smooth

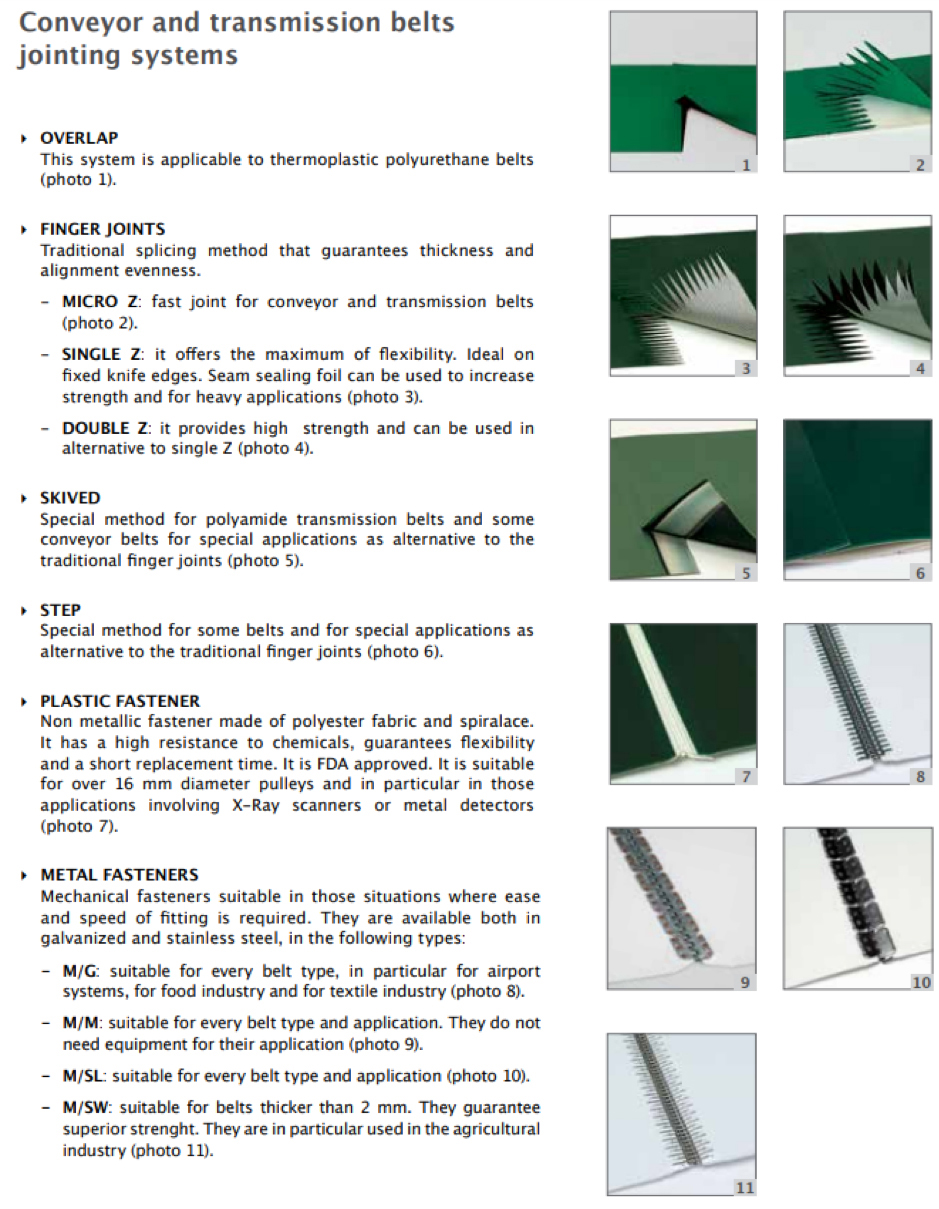

Joining Systems

Power Transmission Belts

Power Transmission Belt (Flat Belt) is a flat looped strip of flexible material, used to mechanically link two or more rotating shafts. They may be used as a source of motion, to efficiently transmit power, or to track relative movement. United Belt provides power transmission belts which are custom made to suit specific industry and application needs or machine design.

1. Flat Belts

2. Leather belts

Telfon Products

The Teflon coating on the conveyor belt prevents products getting stuck. Products can be transported evenly and swiftly, which enhances the production process. Especially packaging industry, where packs with products are sealed using high temperatures.

1. Telfon Belts

2. Telfon Nets

3. Telfon Coated Tapes

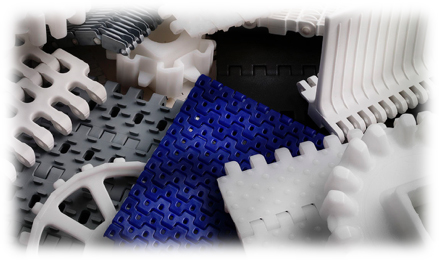

Plastic Modular Belts

Plastic Modular Belt is made up of molded plastic modular links, or belt modules, arranged in rows and normally link by plastic rods. We provide custom-made belts which are available with flights and side guards as an integral part of the belt, and are secured with full-width plastic hinge rods.

1. "Lego-like" Conveyor Belts